When sourcing wooden toys, especially for export to Europe, the USA, Middle East, and Southeast Asia, many new buyers focus heavily on product design, pricing, and certifications — but often overlook one critical factor: printing methods.

In reality, the printing process directly affects:

✔ Product safety compliance

✔ Durability and customer satisfaction

✔ Production cost and MOQ

✔ Brand positioning and retail appeal

As a professional wooden toy manufacturer and exporter serving global wholesalers, distributors, and retailers, Tooky Toy created this guide to help new buyers understand the most common wooden toy printing methods, their pros and cons, and how to choose the right solution for your market.

Why Printing Methods Matter in Wooden Toys

Unlike plastic toys, where colors are molded into the product, wooden toys rely heavily on surface printing and coating techniques to achieve attractive visuals and functional markings.

Choosing the wrong printing method can result in:

- Color fading

- Pattern peeling

- Failed safety tests

- Higher returns and warranty claims

Choosing the right one helps you:

- Meet EN71, ASTM F963, CPSIA compliance

- Control costs while maintaining quality

- Improve shelf appeal and brand consistency

- Reduce long-term sourcing risks

Common Wooden Toy Printing Methods Explained

1. Screen Printing (Silk Screen Printing)

Best for: Letters, numbers, simple patterns, educational toys, puzzles

Screen printing is one of the most widely used wooden toy printing methods. It transfers ink through a mesh stencil onto the wooden surface, with each color printed separately.

Advantages:

✔ High durability and strong ink adhesion

✔ Excellent color saturation

✔ Cost-effective for bulk production

✔ Stable quality for repeat orders

Limitations:

❌ Not suitable for gradients or fine details

❌ Requires screens for each design

Best for buyers: Wholesalers and retailers seeking cost-effective, stable-quality wooden toy production.

2. Heat Transfer Printing

Best for: Cartoon characters, animals, colorful designs, branded toys

Heat transfer printing applies pre-printed film onto wooden surfaces using heat and pressure.

Advantages:

✔ High detail resolution

✔ Supports multi-color and gradient images

✔ Flexible design changes

Limitations:

❌ Slightly lower abrasion resistance than screen printing

❌ Requires surface sealing

Best for buyers: Brands and specialty retailers focused on visual appeal and storytelling design.

3. UV Digital Printing

Best for: Custom wooden toys, small batch orders, private label branding

UV printing sprays ink directly onto wood and cures it instantly using UV light.

Advantages:

✔ No plates required, low MOQ

✔ Excellent image clarity

✔ Perfect for product customization

Limitations:

❌ Higher unit cost

❌ Requires smooth surface preparation

Best for buyers: Startups, eCommerce sellers, and gift brands testing new product lines.

4. Laser Engraving / Wood Burning

Best for: Montessori toys, eco-friendly brands, premium wooden toys

Laser engraving uses heat to carve patterns directly into the wood without ink.

Advantages:

✔ 100% ink-free and chemical-free

✔ Permanent markings

✔ Strong natural and eco-friendly appeal

Limitations:

❌ No color output

❌ Less visual contrast for some designs

Best for buyers: Eco-conscious brands and educational toy retailers targeting sustainability-focused consumers.

Best Wooden Toy Printing Methods by Market

| Market | Preferred Printing Methods | Buyer Priorities |

|---|---|---|

| Europe | UV printing, laser engraving, water-based painting | FSC, eco-safety, natural aesthetics |

| USA | Screen printing, UV printing, heat transfer | Durability, compliance, consistency |

| Middle East | Screen printing, heat transfer | Bright colors, strong visuals |

| Southeast Asia | Screen printing, spray painting | Cost efficiency, stable supply |

Selecting a printing method that works across multiple regions helps buyers streamline SKUs and reduce inventory risks.

Printing Methods & Toy Safety Compliance

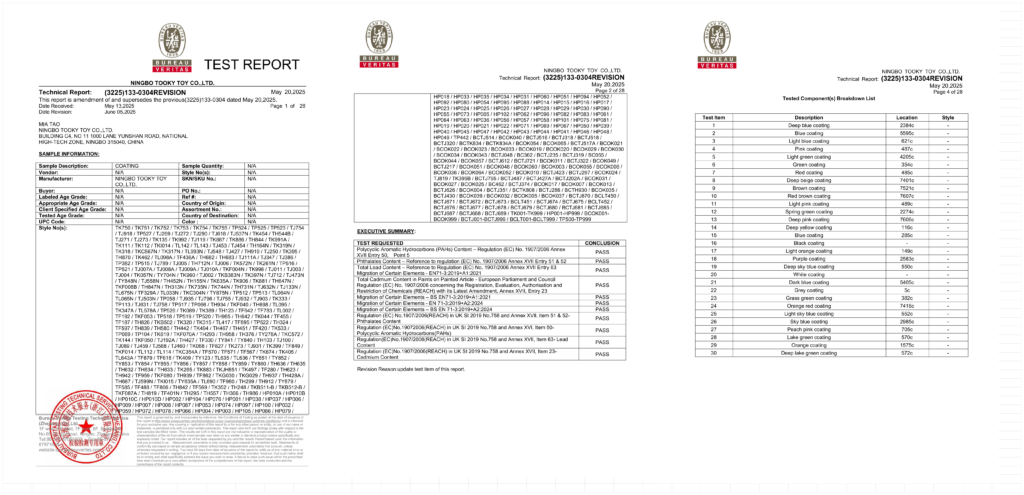

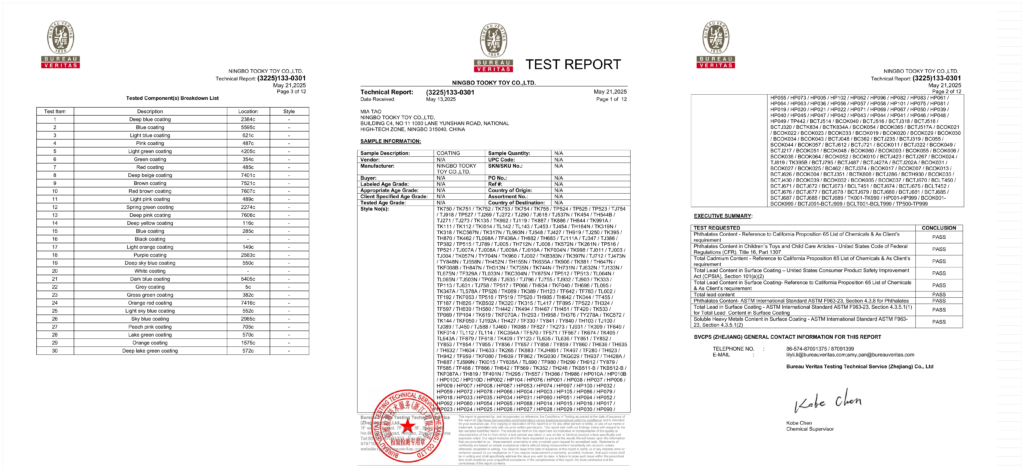

All wooden toys exported to Europe and the USA must comply with:

✔ EN71

✔ ASTM F963

✔ CPSIA

✔ REACH chemical standards

Printing methods directly impact testing success rates.

| Printing Method | Safety Compliance Stability |

|---|---|

| Laser engraving | ⭐⭐⭐⭐⭐ |

| UV digital printing | ⭐⭐⭐⭐ |

| Screen printing (water-based ink) | ⭐⭐⭐⭐ |

| Heat transfer printing | ⭐⭐⭐ |

| Solvent-based painting | ❌ Not recommended |

At Tooky Toy, all printing uses water-based, child-safe inks and supports third-party testing documentation.

How Printing Affects Cost, MOQ, and Production Strategy

| Printing Method | Unit Cost | MOQ Flexibility | Best Use Case |

|---|---|---|---|

| Screen printing | Low | Medium | Core high-volume SKUs |

| Heat transfer | Medium | Medium | Design-focused products |

| UV printing | Higher | Low | Market testing & customization |

| Laser engraving | Medium | Low | Premium & eco collections |

New product testing → UV printing or laser engraving

Scaling best sellers → Screen printing

- Premium positioning → Laser engraving + natural finishes

Common Mistakes New Wooden Toy Buyers Make

❌ Choosing designs based only on samples, not durability

❌ Ignoring testing costs associated with printing methods

❌ Launching too many design SKUs at once

Better approach:

✔ Request abrasion and saliva migration testing data

✔ Optimize printing for long-term compliance

✔ Start with modular, scalable designs

How Tooky Toy Helps Buyers Optimize Printing Choices

As a professional wooden toy manufacturer and exporter with global B2B experience, Tooky Toy offers:

✅ Multi-process sampling comparisons

✅ Market-driven design guidance

✅ Safety compliance documentation

✅ FSC-certified production

✅ MOQ optimization strategies

✅ Custom packaging and branding services

Our goal is not just to manufacture toys — but to help buyers build scalable, compliant, and profitable wooden toy product lines.

Final Thoughts: Printing Methods Are a Strategic Advantage in Wooden Toy Sourcing

For new buyers, understanding wooden toy printing methods is not a technical detail — it’s a business advantage.

The right printing solution improves:

📌 Retail performance

📌 Brand positioning

📌 Safety compliance

📌 Supply chain stability

If you are developing new wooden toy collections or optimizing your existing SKUs, the Tooky Toy team is ready to support your sourcing success.

👉 Contact us today to explore custom wooden toy printing solutions tailored to your market.